Thanks to its characteristics, the Riplast pipe in low density polyethylene is a product capable of offering incredible performance and durability in any climatic condition.

Over the course of 40 years, the Riplast pipe has found strong appreciation from many installers and farmers, comforted by its high and long-lasting performance in the field.

They are specially designed for irrigation systems, lateral branches and small supply pipes from the water reserve to the field.

Riplast pipes have always been appreciated for their technical characteristics, typical of polyethylene pipes, and for their convenience:

Easy installation for lightness and high flexibility.

Reduced pressure drops thanks to the low roughness of the material and its resistance to the onset of encrustations.

Corrosion resistance; It can be installed underground without protection.

Resistant to a wide range of chemicals and resistant to most bacteriological agents present in the soil.

Resistance to atmospheric agents and alterations due to ultraviolet rays, thanks to the carbon black content.

Simplicity of maintenance and repair operations.

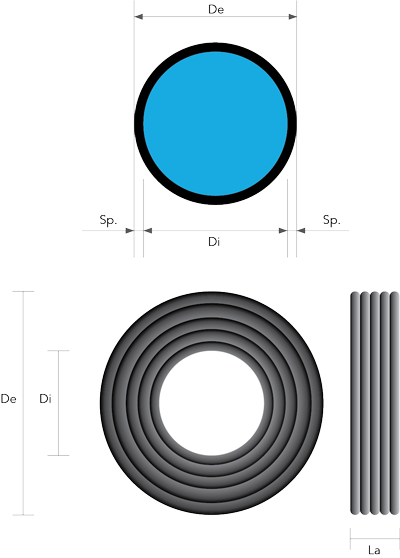

Riplast pipes are available in diameters from ø16 to ø110 mm with 3 different series:

Type 4 – small thickness series

Type 6 – medium thickness series

Type 10 – thick series

The tubes are heat-branded along the generator indelibly and legibly during the manufacturing process.

The marking reads:

All tubes are subjected to strict quality controls before being put on the market, according to a specific self-control plan developed by the company.

To carry out these tests, Soaplast uses its own internal laboratory equipped with modern equipment and qualified technicians, as well as accredited external laboratories.

The self-control plan includes: